- National Retail Chain

- Application Modernization

Revitalizing a Legacy ERP System for Enhanced Efficiency & Scalability

A global manufacturing company partnered with us to modernize their 15-year-old legacy ERP system, which was becoming a bottleneck for operations, lacked scalability, and posed security risks. Through a comprehensive modernization process, we transformed their outdated software into a modern, cloud-based solution, improving performance, enhancing security, and reducing operational costs.

Country

United States

Duration

6 Months

Industry

E-Commerce

Benefits

At Glance

40%

Increase

In operational efficiency

100%

Compliance

GDPR & enhanced security

30%

Reduction

In maintenance costs

25%

Improvement

In decision-making

Project Key Highlights

- Real-Time Data Processing

Enhanced capabilities for managing large volumes of data.

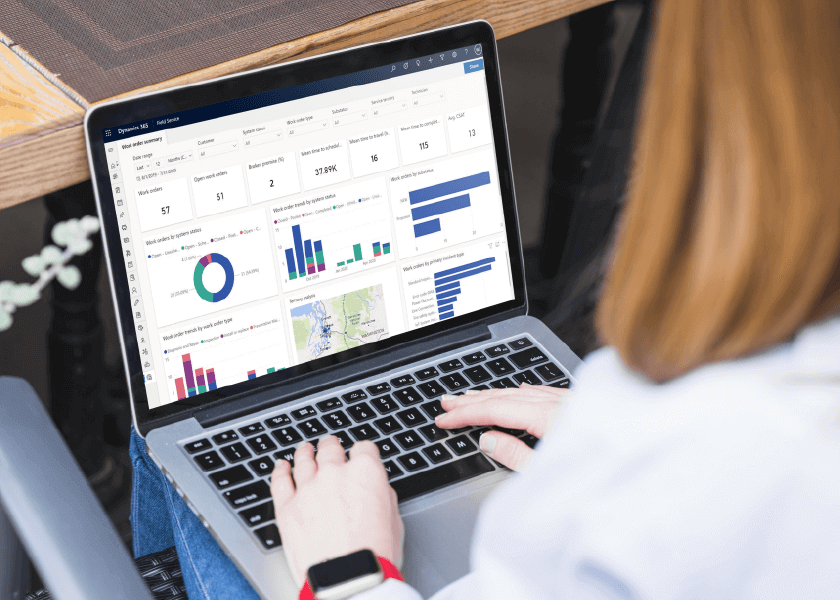

- Advanced Analytics

Visual dashboards for actionable insights.

- Enhanced Security Measures

Compliance with industry standards and regulations.

- User-Friendly Interface

Modern UI for better user engagement.

- Seamless Integration

Compatibility with IoT and third-party applications.

Challenges Faced

By The Client

Performance Bottlenecks

The legacy ERP system struggled to handle the company’s growing data volumes and user demands, causing delays in operations and inefficiencies across the supply chain.

Security Risks

Due to outdated security protocols, the system was vulnerable to breaches and failed to comply with modern data protection regulations like GDPR.

Lack of Integration Capabilities

The system couldn’t integrate with newer tools and third-party applications, hindering the company’s ability to adopt advanced technologies like IoT and AI.

High Maintenance Costs

The legacy system required constant manual intervention and incurred high maintenance costs due to obsolete technologies.

Our Approach

- Assessment & Strategy

We conducted a thorough assessment of the existing ERP system, identifying performance issues, security vulnerabilities, and integration capabilities. Collaborating with the client’s leadership team, we defined a modernization roadmap focused on migrating to a cloud-based architecture while enhancing core functionalities.

- Ongoing Support

Post-launch, we provided proactive continuous monitoring, dedicated support, and timely feature updates to ensure the system’s optimal performance. Our DevOps team also implemented automated scaling solutions to manage fluctuating workloads efficiently.

- Modernization & Integration

We executed the modernization process in phases to ensure minimal disruption to the company’s operations. The system’s backend was restructured to handle large-scale data processing, while the frontend was redesigned for a more intuitive user experience. We integrated Azure Active Directory for enhanced security and Azure IoT Hub for connecting manufacturing devices to the ERP system.

- Design & Planning

Our design phase involved developing a future-proof architecture using Microsoft Azure as the cloud platform, with scalable components built using .NET Core. The new architecture was designed to integrate seamlessly with IoT devices and advanced analytics tools to support real-time monitoring and decision-making.

- Testing & Deployment

The modernized system underwent rigorous testing, including performance benchmarks and security audits, to ensure compliance with international standards. The deployment was carried out seamlessly, with zero downtime, using CI/CD pipelines on Azure DevOps.

Results Achieved

Scalability for Future Growth

The new cloud-based architecture enables the ERP system to scale with the company’s growing needs, supporting thousands of users and managing large data volumes effortlessly.

Cost Savings

By migrating the ERP system to the cloud, the company reduced infrastructure and maintenance costs by 30% while also eliminating the need for frequent manual interventions.

Enhanced Security & Compliance

With the integration of Azure Active Directory and GDPR-compliant protocols, the system’s security posture improved, protecting sensitive data and ensuring full compliance with international regulations.

Real-Time Data Insights

The integration of IoT devices with the ERP system allowed for real-time data collection and analysis, improving decision-making and predictive maintenance across the manufacturing floor.

Improved Operational Efficiency

The modernized ERP system increased the company’s overall operational efficiency by 40%, reducing processing delays and enhancing supply chain management.

Technologies Used

Technology

Description

- Angular

Frontend Development

For a responsive and modern user interface.

- .NET Core

Backend Development

For improved performance and scalability.

- Azure SQL

Database Management

For cloud-based data management.

- Power BI

Reporting & Analytics

For advanced data visualization and real-time insights.

- Microsoft Azure

Cloud Infrastructure

For scalable and secure hosting.

Testimonial

CIO

- Global Manufacturing Company

Let’s bring your idea to life

Your innovative idea deserves a team that can bring it to life. Reach out to us today to discuss your project, and we’ll work with you every step of the way.