Smart Factory Solutions: Revolutionizing

Real-Time Production Management

In the era of Industry 4.0, smart factories are leading the transformation of manufacturing processes. i-verve offers Smart Factory Solutions designed to monitor, control, and optimize production processes in real-time. Our solutions integrate IoT, AI, and advanced analytics to provide end-to-end visibility, enabling businesses to boost efficiency, reduce downtime, and ensure quality. From predictive maintenance to energy optimization, we empower manufacturers to achieve operational excellence.

Why Smart Factory Solutions are Essential?

Real-Time Visibility

Gain instant insights into production performance and equipment health.

Enhanced Productivity

Automate processes and optimize workflows to maximize output.

Predictive Maintenance

Identify and address potential issues before they lead to costly downtime.

Improved Quality Assurance

Monitor quality parameters in real-time to ensure consistent product standards.

Energy Efficiency

Optimize resource usage and reduce energy consumption with smart monitoring tools.

Key Features of Smart Factory Solutions

IoT-Enabled Connectivity

- Connect devices, machines, and systems to a unified network for seamless communication.

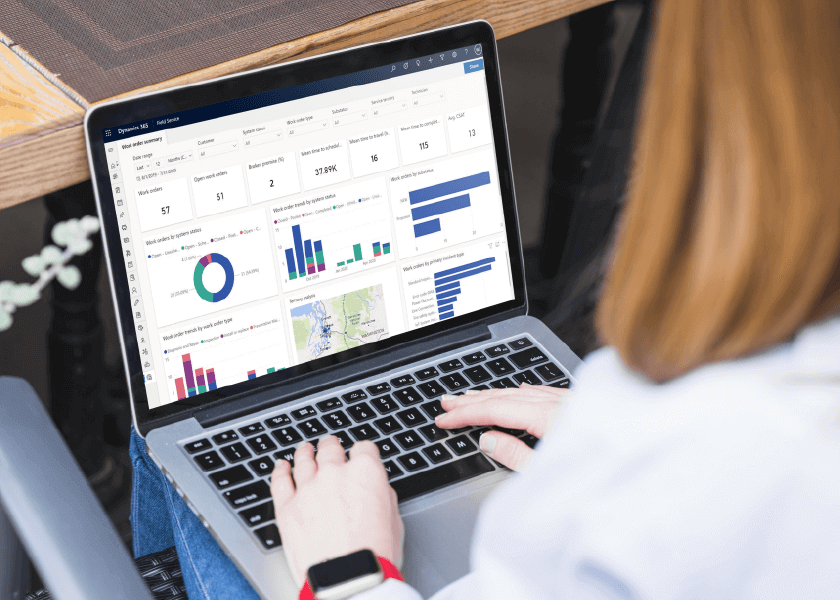

Real-Time Data Analytics

- Process and visualize data to identify inefficiencies and improve decision-making.

AI-Powered Predictive Maintenance

- Use machine learning to predict and prevent equipment failures.

Automation and Robotics

- Implement automated workflows to enhance speed and accuracy in production.

Digital Twin Integration

- Create virtual replicas of production systems for testing and simulation.

Energy Management Systems

- Monitor energy consumption and implement strategies for resource optimization.

Customizable Dashboards

- Access real-time metrics and performance reports through intuitive interfaces.

Seamless System Integration

- Integrate smart factory tools with ERP, MES, and SCM systems for unified operations.

Benefits of Smart Factory Solutions

Increased Operational Efficiency

Streamline workflows and eliminate bottlenecks to boost production.

Reduced Downtime

Proactively address issues with predictive maintenance and real-time monitoring.

Enhanced Product Quality

Maintain consistent quality standards through continuous monitoring and automation.

Cost Optimization

Reduce operational costs by optimizing energy usage and minimizing waste.

Improved Decision-Making

Leverage data-driven insights for strategic planning and process improvements.

Scalability for Growth

Adapt systems to meet the demands of expanding operations and markets.

Sustainability

Align with environmental goals by optimizing resource consumption and reducing emissions.

Our Smart Factory Solutions Process

Assessment and Design

Analyze your manufacturing processes and design tailored smart factory solutions.

System Integration

Connect IoT devices, sensors, and machines to a unified network.

Data Collection and Processing

Gather real-time data from production processes and equipment.

Analytics and Insights

Use AI and advanced analytics to identify inefficiencies and opportunities for improvement.

Automation Implementation

Deploy robotic and automated workflows to enhance speed and accuracy.

Real-Time Monitoring

Continuously monitor production performance and receive alerts for anomalies.

Optimization and Scaling

Refine processes based on insights and scale systems to accommodate growth.

Why Choose i-verve?

Expertise in Smart Factory Solutions

Years of experience delivering cutting-edge manufacturing systems for diverse industries.

Advanced Technology Integration

Combine IoT, AI, and robotics to create fully integrated smart factory ecosystems.

Customizable and Scalable Solutions

Tailored systems designed to grow with your business and meet unique requirements.

Seamless System Compatibility

Ensure smooth integration with your existing ERP, MES, and SCM platforms.

End-to-End Support

Comprehensive guidance from consultation and implementation to training and optimization.

Focus on ROI

Deliver measurable improvements in efficiency, cost savings, and production output.

Commitment to Sustainability

Help businesses meet environmental and energy efficiency goals.

Revolutionize Your Manufacturing Processes with Smart Factory Solutions.

Ready to transform your factory operations with real-time monitoring and automation? Discover how i-verve Smart Factory Solutions can drive efficiency, reduce costs, and enhance quality.